MRP

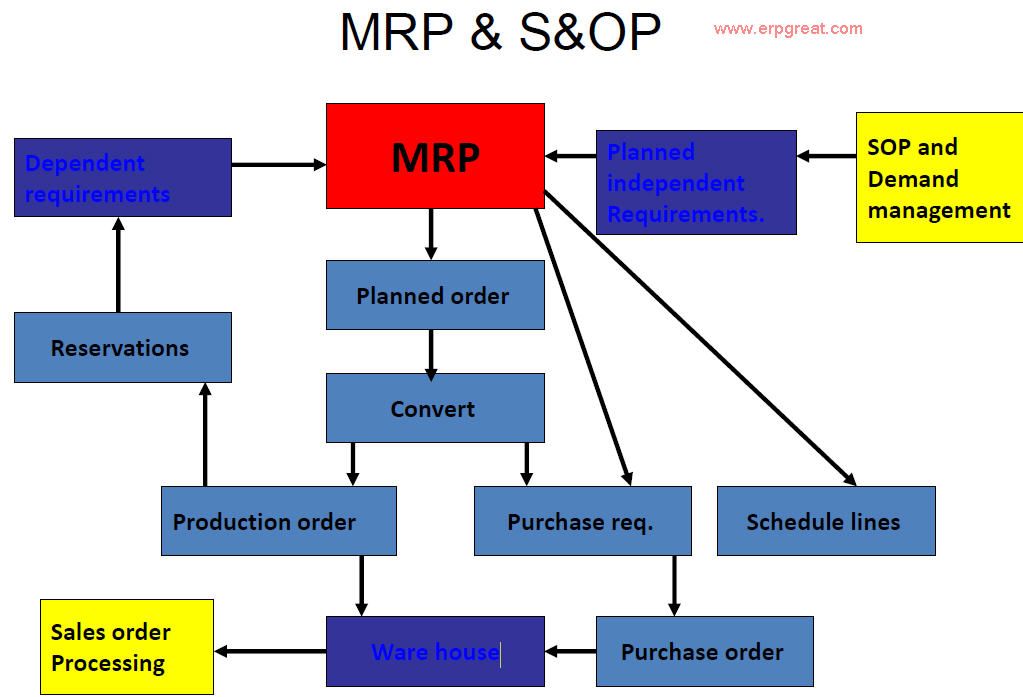

MRP is a tool which helps in planning the requirement quantities and schedules of a given material. It not only ensures availability of the material for which MRP is carried out, but also ensures availability of the components (of all the BOM levels) below in the BOM structure. It is DEMAMD driven.

S&OP

SOP is a forecasting tool enabling you to set up sales, production, and other supply chain targets based on existing, future, or historical data. SOP is most suitable for planning finished goods, and not for material component planning. SOP is made up of two application components namely, Standard SOP and Flexible Planning.

SOP plans are passed on to Demand Management (DEM) in the form of independent requirements, which in turn is fed into MPS (Master Production Scheduling) and MRP (Material Requirements Planning). The results of SOP can be passed on to profitability analysis, cost center accounting, and activity-based costing.