Consumption-based planning procedures use past consumption data (historical data) to calculate future requirements with the help of the material forecast or static planning procedures.

Consumption-based planning procedures have no reference to the master plan. This means that the net requirements calculation is not triggered by an independent or a dependent requirement. Instead, the net requirements calculation is triggered when stock levels fall below a reorder point or by forecast requirements calculated from past consumption data.

The advantage of this type of planning is that it is easy to use and you do not require extensive data.

SAP uses the below MRP procedures

- Reorder Point Planning

- Forecast-Based Planning

- Time-phased planning

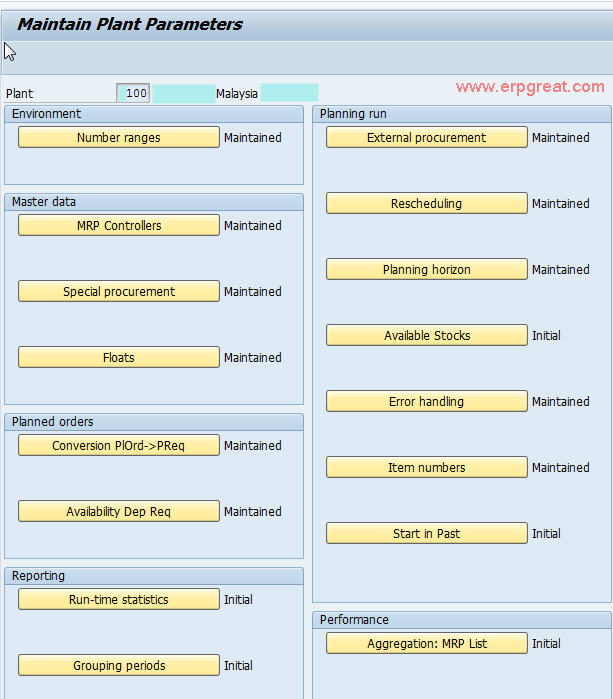

a) T-Code : OMI8 - Maintain Plant Parameters

SPRO -> Materials Management -> Consumption-Based Planning -> Plant Parameters -> Carry Out Overall Maintenance of Plant Parameters

b) T-Code : OPPR - Maintain MRP Group (CBP can also be done without MRP Group settings)

SPRO -> Materials Management -> Consumption-Based Planning -> MRP groups -> Carry Out Overall Maintenance of MRP Groups

Master Data Settings

a) Material Master needs to be maintained with MRP Views

b) MRP type - VB (if manual Reorder point is used) and Lot Size - HB ( Replenish to maximum stock level)

There are different MRP types for Consumption Based Planning which comes standard e.g. V1, V2, VM etc.

For example we consider Manual Reorder point planning,

we have set the reorder level as 5 and maximum stock level is 20, we will

consider the current stock is 4, planning file entry is created once the

stock level falls below the reorder point level, when MRP is run a Procurement

proposal is created for 16nos (consider the current stock is 4).

Other Explanation

Configurations for CBP as explained before.

a) Plant Parameters - T-Code : OMI8, when you execute this T-Code you will get several tabs like for example Number ranges, MRP Controllers etc. you need to maintain those are relevant like:

MRP Controllers, Number ranges, Available stock most of these tabs are mandatory configurations.

MRP Controllers - Defined and assigned to the plants, MRP Controllers are the planners who are responsible when it comes to the materials.

Number ranges : Planned orders, Purchase requisitions

Available Stock : whether Stocks in transit, Blocked stock, Restricted stock are to be considered or not.

Planning Horizon - 100 days. During MRP run, those materials for which planning file entry is created and within the next 100 days will be calculated for MRP.

b) MRP Group is not a mandatory configuration.

In case you need have configured new document type this can be entered in the "External Procurement per MRP Group" tab and this MRP group can be assigned to the material mster, based on this assignment the document type is picked up.

Each tab has its own significance.